- Home

- Resins

- Standard Resins

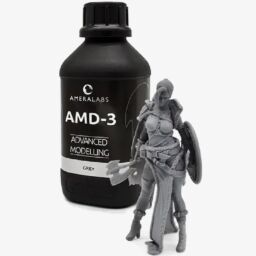

- AmeraLabs AMD-3 Grey

AmeraLabs AMD-3 Grey

£36.00 – £264.00 (incl. VAT)

AmeraLabs AMD-3 Grey is a multifunctional resin for engineering and prototyping, enabling the manufacture of products with great accuracy, suitable for various applications. AMD-3 properties allow creating products that are reliable, hard and do not deform over time. Recommended for prototyping, silicone mould casting, electro-metal plating, jigs and fixtures.

AmeraLabs AMD-3 Grey

AmeraLabs AMD-3 Grey is a multifunctional resin for engineering and prototyping, enabling the manufacture of products with great accuracy, suitable for various applications. AMD-3 properties allow creating products that are reliable, hard and do not deform over time. Recommended for prototyping, silicone mould casting, electro-metal plating, jigs and fixtures.

What are the Benefits?

- Fast curing (probably the fastest curing material on the market)

- High resolution

- Paintable surface

- Low odour

- Dimensional accuracy and stability

- Compatible with most LCD resin 3D printers

Printing Tips

- Level your build plate.

- If it’s your first print with this resin, print something small first.

- Find initial printing settings here: AmeraLabs resin settings.

- Use support column thickness of 1.5-2mm, support tip thickness of 0.2-0.6mm.

- Use attachment layer.

- Hollow your models.

- Use slower lift speeds. 5mm/min for bottom layers, 40-60mm/min for normal layers.

Resin Specification

Resources / Downloads

Resin Key Features

AMD-3 is probably the FASTEST curing resin for LCD printers!

Designed to work even on low powered LED/LCD 3D printers equipped with LED light sources emitting 365-420nm UV light. Compatible with colour and monochrome LCD 3D printers.

We have recommended 3D printing settings for many 3D printers here: AmeraLabs resin settings.

AMD-3 LED resin produces dimensionally accurate and stable prints. Due to its stiffness and a fair amount of hardness it can sustain straight edges and print out even the tiniest features. Supports do not bend during printing, keeping the model in place throughout the whole printing session and giving a higher rate of success with complex prints. It exhibits low shrinkage so the print will not deform during post-curing stage and will not crack over a long period of time.

Resin is available in two colours: black and grey. AMD-3 is carefully pigmented to get an ideal colour that expresses the most intricate details. Colour is almost fully opaque. Surface is glossy and hard (80-90 Shore D). After post-cure, the print does not feel sticky or tacky and is pleasant to touch. It does not scratch very easily. It can be primed and painted with most popular paints. Due to its hardness, material surface can be polished to remove any layer lines, support marks or other imperfections. This allows using this material for printing masters for applications where smooth surface is needed.

Water absorption is less than 0.2%. This means, that your models will not deform due to moisture or exposure to IPA. It is even resistant to some acids.

Viscosity of this material is relatively low – around 180-200cps – so cleaning is quite easy.

If you do not have an ultrasonic cleaner or prefer cleaning with ordinary IPA baths, this is our 4 easy steps cleaning procedure:

- After taking your printed object off the build plate leave it submerged in the IPA bath for 2 minutes.

- Swirl the IPA bath with printed part in it actively for another 2 minutes.

- After swirling, leave it still, but fully submerged for another 2 minutes.

- Finally, swirl the bath actively again for 2 minutes.

Evaluate cleaning results and repeat this procedure only once (if needed) with clean IPA.

If you prefer cleaning with an ultrasonic cleaner, we recommend to put a printed part into the container with IPA, close it well and put

the container into the ultrasonic cleaner filled with water. Leave it for no more than 10 minutes. No additional heating is necessary.

If you use Phrozen Wash & Cure Kit, leave the printed object submerged in IPA for approx. 6 minutes. Depending on the results, you can repeat this step again and leave for additional 6 minutes.

It is easier to remove supports before post-curing. However, you can also post-cure a print with supports and remove them later. Depending on the model this can help to obtain better geometries if you have such goal. Post-curing time depends on your curing station, it can vary from 5 minutes to 1 hour (until the surface of your 3D print becomes non-sticky). You should post-cure immediately after cleaning and drying. After proper post-curing surface of AMD-3 printed objects should be completely non-sticky and very hard to scratch.

Reviews

There are no reviews yet.