- Home

- Resins

- Functional / Engineering Resins

- AmeraLabs SiOmaster Grey

AmeraLabs SiOmaster Grey

£90.00 (incl. VAT)

AmeraLabs SiOmaster Grey resin was developed for professionals utilising spin casting and SiOCAST injection moulding machines. SiOmaster resin allows you to 3D print master models that can withstand a high-temperature silicone rubber vulcanisation process up to 180°C multiple times without breaking or deforming. This enables companies to reuse their master models multiple times to produce several moulds.

AmeraLabs SiOmaster Grey

What are the Benefits?

- Withstands vulcanisation up to 180° C

- Low shrinkage

- Excellent details

- Easy to remove supports and sand

- Dimensional accurate

- Compatible with most LCD and DLP resin 3D printers

Printing Tips

- Level your build plate.

- If it’s your first print with this resin, print something small first.

- Find initial printing settings here: AmeraLabs resin settings.

- Use support column thickness of 1.5-2mm, support tip thickness of 0.2-0.6mm.

- Use attachment layer.

- Hollow your models.

- Use slower lift speeds. 5mm/min for bottom layers, 40-60mm/min for normal layers.

Vulcanising Tips

Taking Details from Digital to Physical

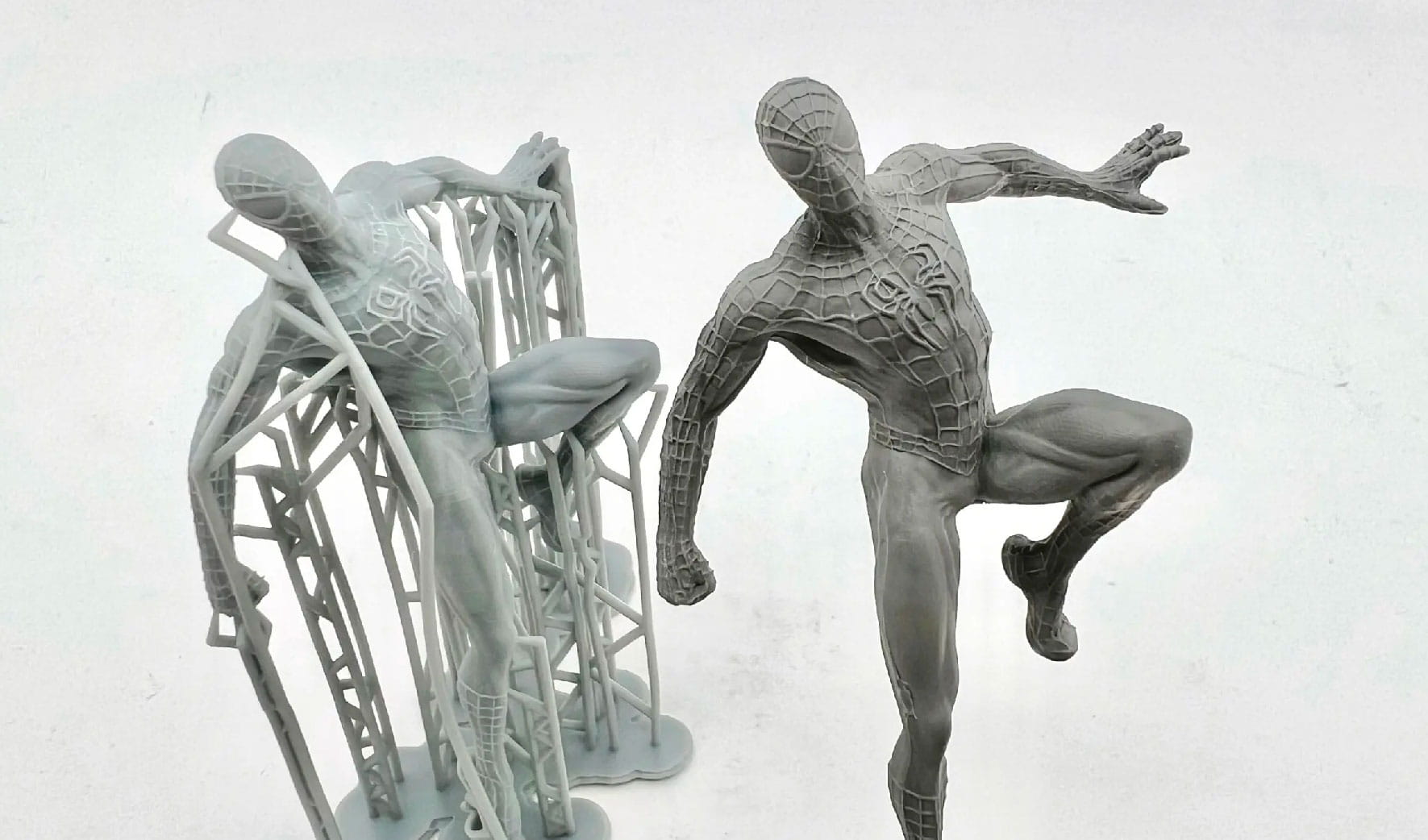

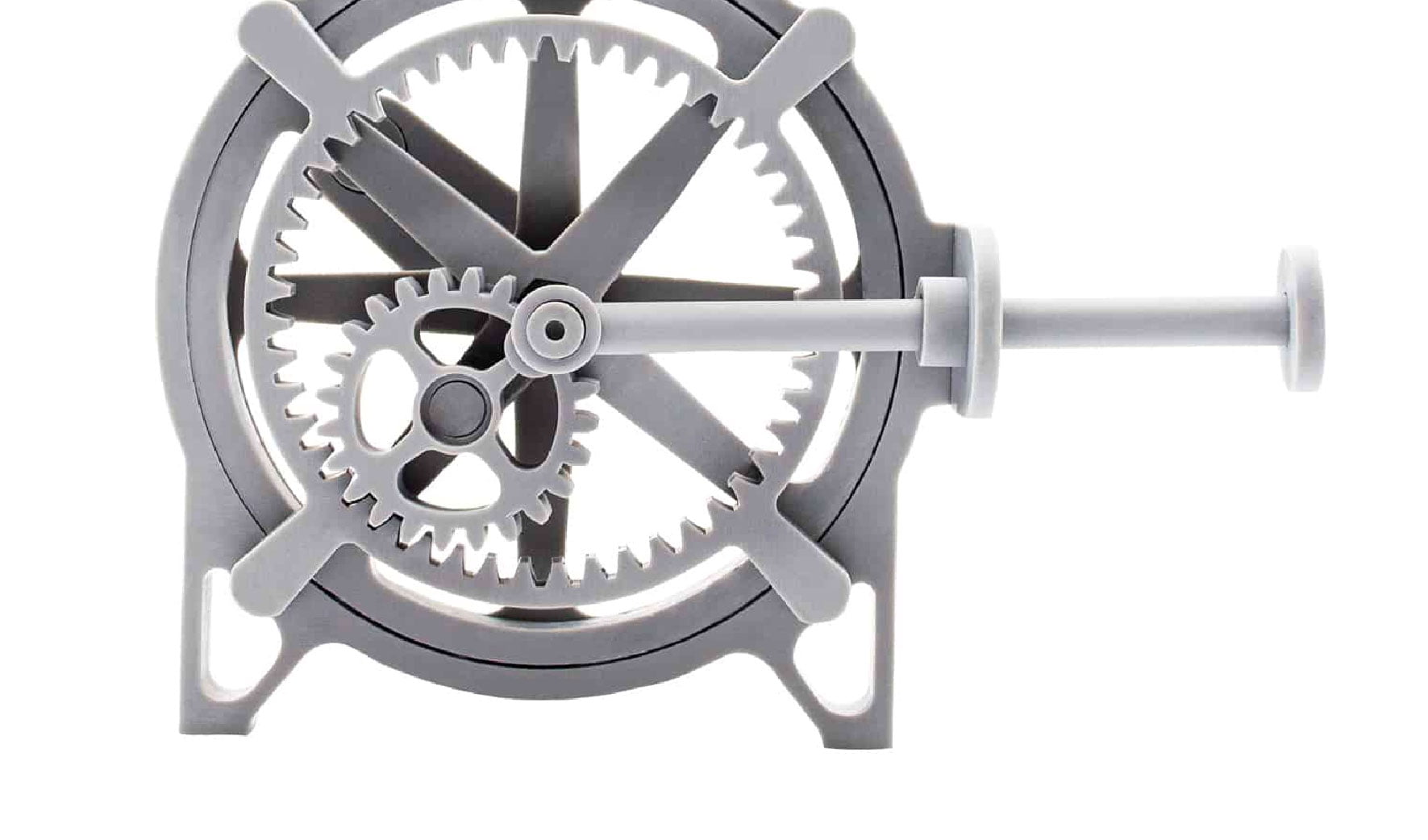

3D printing has become a go-to solution for the production of many models: industrial parts, prototypes, and miniatures. However, once the production quantities increase to the hundreds, it makes sense to switch to spin casting in metal or injection moulding with SiOCAST machines to produce plastic parts. In such cases, 3D printing is used just as a first step to turning a digital model into a physical object. This 3D printed model is then placed into silicone to create a mould, which, in turn, will be used to produce multiple copies of that initial 3D printed model.

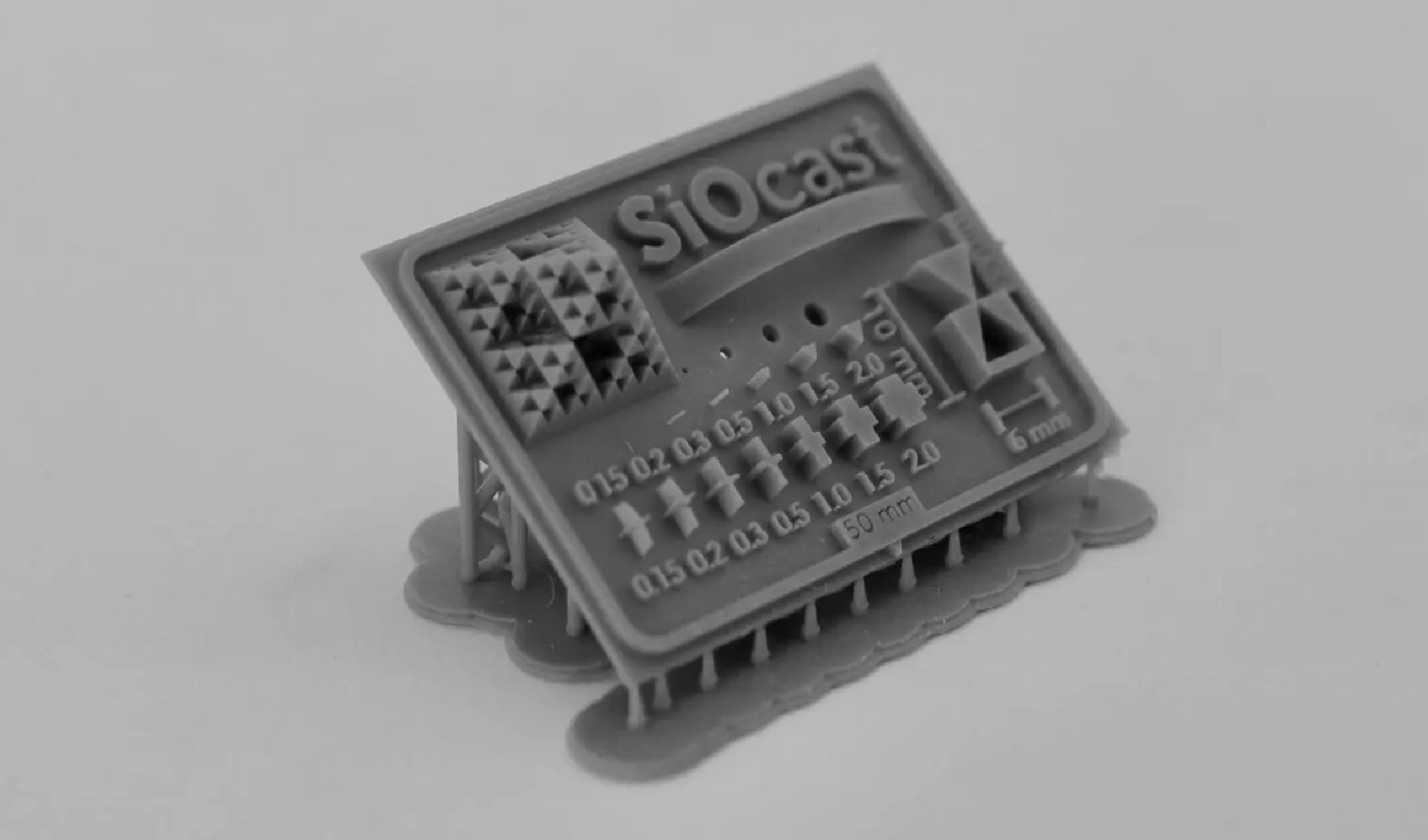

Anyone who has ever tried making silicone moulds knows that silicone takes the tiniest details from the master model and replicates that in the final product. Therefore, the 3D printed master models that are being copied have to capture details just as the digital designer imagined them. SiOmaster resin does exactly that.

Not only does it print great and reproduces all details of the model, but it also has a balanced amount of flexibility. This flexibility is crucial during the silicone vulcanisation process. During this process, the silicone is placed under high pressure and high temperature inside a steel frame. Other 3D printing resins with high-temperature resistance will break due to the high pressure. On the other hand, flexible resins will deform due to high temperatures and produce deformed moulds. SiOmaster resin has just enough flexibility to withstand pressure and sufficient temperature resistance to stay stiff enough at higher temperatures. All of this prevents tiny details from breaking during the vulcanisation process while maintaining the dimensional accuracy of the parts.

Resin Key Features

This resin is compatible with most LCD and DLP resin 3D printers equipped with light sources emitting 385-420nm UV light. It is compatible with both colour and monochrome LCD 3D printers.

We have recommended 3D printing settings for many 3D printers here: AmeraLabs resin settings.

SiOmaster resin works perfectly with SiOmold silicones from SiOCAST.

We have also tried several other silicones from different manufacturers and had no issues with any of them.

We were able to make moulds with silicones vulcanised at temperatures ranging from 90° to 180° C.

This 3D material should not be left submerged in solvents for extended periods of time. By all means, do not leave the material submerged in IPA or any other liquid for more than 40 minutes. Doing so might ruin your models and affect the final properties of the polymer material.

If you use Phrozen Wash & Cure Kit, leave the printed object submerged in IPA for approx. 12 minutes. Depending on the results, you can repeat this step again and leave for additional 6 minutes.

If you prefer cleaning with ordinary IPA baths, this is our easy four-step cleaning procedure:

- After taking your printed object off the build plate, leave it submerged in the IPA bath for 10 minutes.

- Swirl the IPA bath with our part in it actively for another one minute.

- After swirling, leave it undisturbed, but fully submerged for another 10 minutes. At this point, it would be wise to change the IPA to a clean one.

- Finally, swirl the bath actively again for one minute.

- Evaluate the cleaning results and repeat this procedure only once (if needed).

If you prefer cleaning with an ultrasonic cleaner, we recommend placing a printed part into the container with IPA, closing it well, and putting the container into the ultrasonic cleaner filled with water. Leave it for no more than 10 minutes. No additional heating is necessary.

With a proper support strategy, support removal is easy. Use a high density of supports with 0.2 – 0.6 mm tips. Since printed models are a bit soft before post-curing, you will be able to peel off your supports easily.

A few more tips:

- It’s easier to remove supports right after cleaning and before post-curing.

- However, some complicated models might warp a little bit during post-curing. Thus, in some cases, you might want to remove supports after post-curing. Supports will keep your model in place and won’t let it deform.

- If you have used thicker supports and it is difficult to remove supports, use a heat gun or a bath of hot water to heat up your print. This will make supports softer and easier to remove.

Post-curing time depends on your curing station. It can vary from five minutes to one hour (until the surface of your 3D print becomes non-sticky). You should post-cure immediately after cleaning and drying. After proper post-curing, the surface of SiOmaster printed resin models should be completely non-sticky and hard to scratch.

Models that are post-cured longer will be stiffer and have lower flexibility. So if you find that some of your 3D printed masters bend during vulcanisation, try post-curing the 3D printed models longer. This will make them stiffer and help with maintaining accurate geometries.

On the other hand, models that were post-cured for a very long time will handle fewer vulcanisation cycles before breaking.

Reviews

There are no reviews yet.